Integrated Approach to Manufacturing Excellence #

Fong Prean is situated in a renowned screw industry cluster, enabling access to a robust and high-quality supply chain. Our manufacturing process is meticulously structured, covering every stage from raw material to final packaging, ensuring both efficiency and product integrity.

Comprehensive Manufacturing Workflow #

-

Wire Processing: All incoming wire materials undergo rigorous testing and certification, including checks for non-radiative contamination, to guarantee safety and compliance.

-

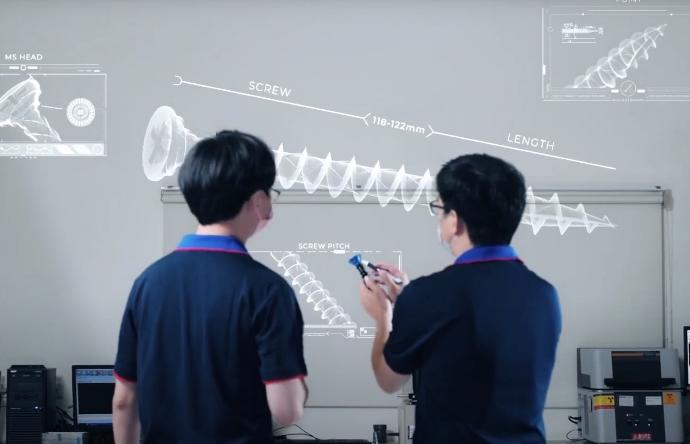

Heading, Point, and Threading: Each step in the forming process is subject to thorough inspections, maintaining consistency and precision throughout production.

-

In-House Heat Treatment: We perform heat treatment internally, followed by detailed inspections to ensure optimal mechanical properties and durability.

-

Plating and Final Inspection: Products receive surface treatments as required, with quality control teams conducting final inspections and generating test reports for every batch.

-

Packaging and Traceability: Every carton is stamped with a LOT number for traceability. We also heat-treat our wooden pallets and offer paper pallet options to meet diverse shipping needs.

-

Container Stuffing: Before shipment, containers are deep-cleaned to prevent contamination from seeds or other pollutants, supporting global export standards.

Commitment to Customization and Continuous Improvement #

Beyond our extensive range of standard products, Fong Prean specializes in developing tailored packaging solutions to meet unique customer requirements. Our approach is rooted in problem-solving, customer satisfaction, and ongoing research and development. We are dedicated to continuous improvement and delivering excellence through our OEM/ODM services.

For more information or to discuss your specific needs, contact us.